Welcome to BioReSteel

Valorization of wet biomass residues for sustainable steel production with efficient nutrient recycling

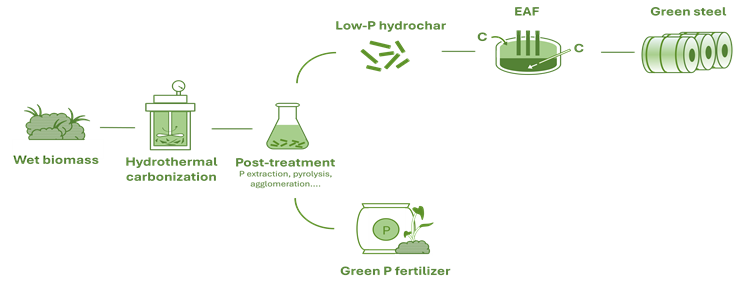

As one carbon neutral source, biocoal will play an important role to facilitate the transition of the European steel industry towards processes decarbonization. The BioReSteel project focuses on exploring, developing and utilizing hydrochar (one type of biocoal), derived from various locally available biomass residues via the hydrothermal carbonization (HTC) process, in the electric arc furnace (EAF) process. HTC unblocks to valorization of residual wet biomass feedstocks, which makes the hydrochar more economically competitive. Given the abundant biomass residues available in Europe, the hydrochar produced from only a few percent (< 2%) is sufficient to supply all operating EAF steel plants in Europe. By estimation, around 840,000 t fossil coal can be substituted by hydrochar at today’s steel production level from EAF process, leading to a reduced fossil CO2 emission of about 2.5 Mt per year. As additional sustainability aspects, phosphorus from residual biomass will be returned into circular economy saving resources of a critical raw material. In addition, heavy metals will be collected for decontamination of products and environment.

The project covers the whole value chain from biomass feedstocks, hydrochar production by an industrial HTC plant, up to its use in the EAF steelmaking of green steel. The project considers all technical, economic and sustainability aspects.

The industrial EAF trials will be performed at three EAF plants to test hydrochar injection, hydrochar top charging and bio-oxides agglomerates in order to prove the concept’s flexibility and generality.

Objective: to replace fossil carbon in the electric arc furnace by biocoal, produced from low-value locally available wet biomass residues by means of a hydrothermal carbonization process.

Methodology: The BioReSteel concept will be proved by an experimental study by the means of laboratory and EAF testbed trials. The industrial EAF trials will be performed at three EAF plants to test hydrochar injection, hydrochar top charging and bio-oxides agglomerates in order to prove the concept’s flexibility and generality.

The value chain in BioReSteel project

Group Manager, Recycling and Environment

Department of Metallurgy

+46 (0)70 634 85 55

Chuan.Wang@swerim.se

www.swerim.se